Crusher is a relatively common equipment in the mining industry, and the equipment type is more diverse, such as jaw crusher, impact crusher, cone crusher, etc. These crushers have large crushing ratio, good finished grain shape, low energy consumption, convenient maintenance and other advantages, favored by the majority of users. Here is a brief introduction to vertical shaft impact crusher. What is the difference between it and other crusher equipment?

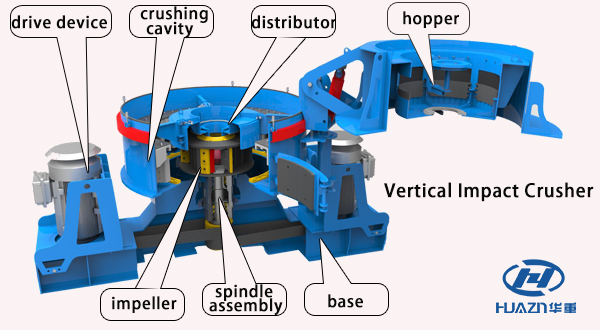

First of all, let’s understand the working principle of vertical shaft impact crusher.

The material falls into the hopper and accelerates through the feeding hole into the rotating impeller. Then it is shot out from the impeller, first of all, it impacts with another part of the material that is free falling after rebound, and then it impacts with the vortex lining in the vortex chamber (stone beat stone). It is first bounced to the top of the crushing chamber, and then deflects downward to collide with the material emitted from the impeller runner to form a continuous material curtain, and then discharged through the lower discharge port.

It is because of the working principle of vertical shaft impact crusher, this kind of crusher is widely used in cement raw material and clinker finely, also used in dolomite, flint clay, lead-zinc mine, serpentine, blast furnace slag, coal gangue, phosphate rock and other medium hard materials, especially for the artificial sand of limestone, dolomite, granite, and basalt, or road pavement stone processing and crushing.

Vertical shaft impact crusher is widely used in these industries because of its performance advantages. The particle shape of the finished product processed by vertical shaft impact crusher is good. In addition, the vertical shaft impact crusher is suitable for crushing medium and super hard materials, and the crusher has little influence on the moisture content when processing these materials, and the moisture content can reach about 8%. In terms of maintenance, this kind of crusher uses the principle of stone beat stone, the impeller lining wear is small, convenience for maintenance.