Granite, known for its high hardness, compressive strength, and abrasiveness, is one of the most challenging raw materials to process in the mining and construction industries. A common question among professionals is whether a hammer crusher is suitable for crushing granite. This article explores the answer and introduces the most effective equipment for granite crushing.

Can Hammer Crusher Crush Granite?

Technically, a hammer crusher can process granite, but it is not the recommended choice for medium to high-hardness granite in most industrial applications. The reasons are:

Principle Limitations: Hammer crushers apply impact force through high-speed rotating hammers. Granite’s high compressive strength (typically 100-250 MPa) and crystalline structure make it highly resistant to this type of sudden, shear-oriented impact.

Severe Wear: Granite is highly abrasive. The hammers, impact plates, and liners in a hammer crusher would wear down at an extremely rapid rate when processing granite. This leads to frequent downtime for maintenance and replacement, significantly increasing operational costs.

Poor Product Shape: The impact from hammers tends to produce excessive internal fractures in the hard granite, often resulting in a finished product with a high percentage of flaky or irregularly shaped particles. This is unsuitable for high-grade applications like concrete aggregate or asphalt paving, where a cubical shape is preferred for strength and workability.

Low Efficiency and High Energy Cost: Overcoming granite’s hardness with a hammer crusher requires tremendous energy, making the process inefficient compared to equipment designed specifically for hard rock.

What Equipment is Used to Crush Granite?

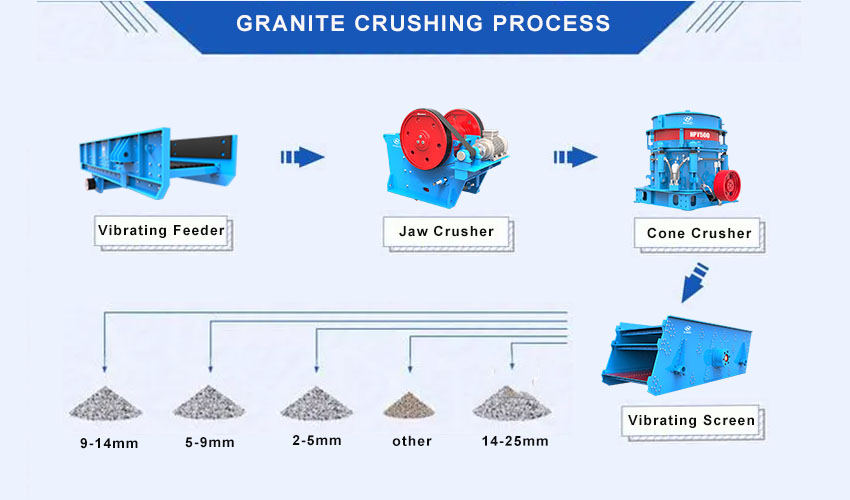

For efficient and economical granite crushing, a multi-stage crushing circuit using specialized equipment is essential. The typical configuration involves three stages: primary, secondary, and tertiary crushing.

- Primary Crushing: Jaw Crusher

Jaw crusher has robust design, with a fixed and a movable jaw plate, applies strong compressive force to break large granite (often up to 1 meter or more in size) into smaller pieces (typically 150-250 mm).

- Secondary Crushing: Cone Crusher

The crushed granite from the jaw crusher is then fed to a cone crusher for secondary crushing. Cone crushers are the ideal choice for hard and abrasive materials.

- Tertiary/Final Crushing: Cone Crusher or Vertical Shaft Impact Crusher

For producing fine aggregates or sand, a third stage is employed.

Cone crusher (fine crushing): A multi-cylinder cone crusher can be used for tertiary crushing to achieve well-shaped, smaller aggregates.

Vertical Shaft Impact Crusher (VSI): For the specific purpose of manufacturing high-quality manufactured sand from granite, a VSI crusher is unparalleled. It uses a high-speed rotor to throw rock against anvils or rock liners, utilizing the “stone-beat-stone” or “stone-beat-iron” principle. This process optimally fractures the granite along its natural cleavage lines, producing perfectly cubical, well-graded sand with the right texture for concrete and asphalt.

In summary, while a hammer crusher is not a practical solution for granite, a well-designed circuit using a jaw crusher for primary crushing, followed by a cone crusher for secondary and tertiary stages, and potentially a VSI crusher for sand making, provides the most effective, reliable, and economical method for processing this tough and valuable rock. Investing in the right equipment specifically engineered for hard, abrasive materials is crucial for achieving high productivity, low operating costs, and premium product quality in granite crushing operations.