What equipment is needed for sand and gravel plant?

1. Raw material silo

A raw material silo is defined as a facility where the raw materials utilized in production are stored. This kind of warehouse typically features a large scale and commonly has a spacious storage yard. It serves as an essential component for large – scale sand and gravel plants, while small – scale sand and gravel plants have the option to utilize it.

2. Feeding equipment

Vibrating feeder is the key equipment in this stage. It can feed block and granular materials uniformly, regularly and continuously into the crushing equipment.

3. Crushing equipment

Jaw crusher, cone crusher, impact crusher, and hammer crusher are the common used crushing equipment. Each machinery plays different role in the production line. There are various types of configuration of these equipment that selected according to the actual production requirements.

4. Sand making equipment

Vertical shaft sand making machine directly influences the quality of produced artificial sand. VSI sand making machine is highly favored by customers because it has both sand making and shaping function, and the finished products it produces have uniform particle shape, size and reasonable gradation.

5. Screening equipment

Vibrating screens are capable of inspecting the qualification of each processing step in the sand-making production line, which serves as a crucial guarantee for enhancing the yield of finished products. After passing through the vibrating screen, the qualified products can proceed to the next process, whereas those that do not meet the requirements need to be reprocessed.

6. Sand washing equipment

The sand washing machine is a crucial equipment for the washing and screening of sand and gravel at present. Its primary function is to eliminate impurities from the finished sand and gravel products, thereby enhancing the purity of the finished sand and gravel.

7. Conveying equipment

The conveyor belt, also known as the belt conveyor, is an important piece of equipment that connects the entire production line, playing a role in carrying and transporting materials.

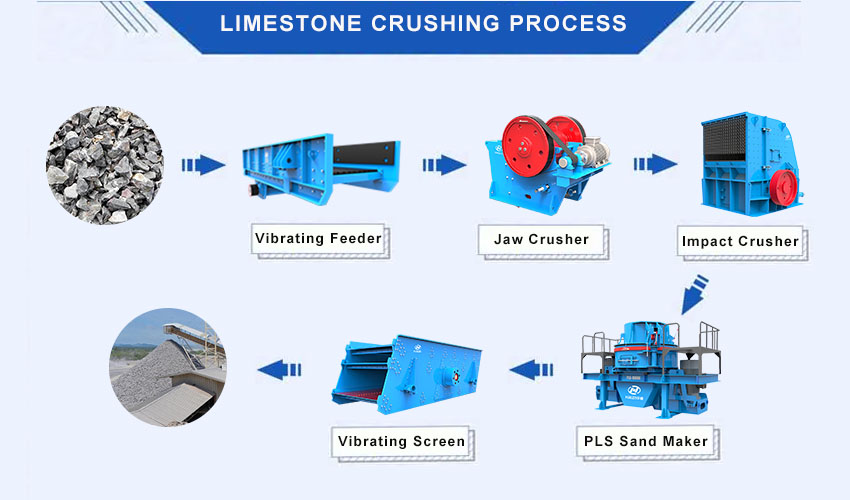

The process flow of the sand and gravel crushing production line

A complete sand and gravel crushing production process includes: raw materials – feeding – coarse crushing – fine crushing – screening – sand making – sand washing – conveying – finished products.

Raw materials enter the vibrating feeder from the silo, and then are sent by the vibrating feeder to the jaw crusher for coarse crushing. After coarse crushing, the materials are conveyed by the conveyor to the impact crusher or cone crusher for fine crushing. After fine crushing, the materials are conveyed by the conveyor to the vibrating screen for screening. If they do not meet the feed particle size requirements of the sand making machine, the materials are returned to the impact crusher or cone crusher for further crushing. The materials that meet the feed particle size requirements are sent into the sand making machine for sand making and shaping. After screening here, they enter the sand washing machine for cleaning. After cleaning, they are conveyed to the finished product pile by the finished product conveyor belt.

Recommendations for sand and gravel crushing equipment manufacturers

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.