When it comes to cleaning sand more effectively, certain types of sand washing machines are designed to produce cleaner, higher-quality sand by removing impurities like dust, clay, and organic matter. Here are the most efficient options:

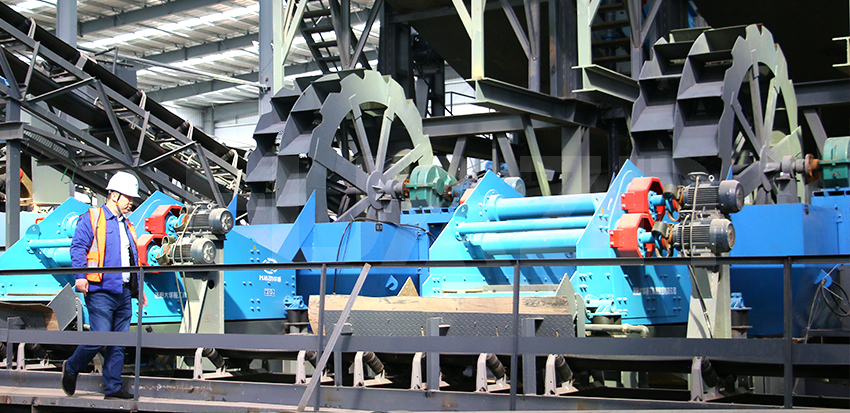

Bucket Wheel Sand Washing Machine

Working principle: Uses a wheel-like structure to scoop and wash sand, separating impurities through agitation and water rinsing.

Applied material: Medium to fine sand with moderate clay content.

Cleaning efficiency: Good for general-purpose washing but may require additional steps for very fine particles.

Spiral Sand Washing Machine

Working principle: A spiral screw stirs and lifts sand while water flushes out impurities.

Applied material: Coarse sand and gravel with heavy clay contamination.

Cleaning efficiency: Better for larger particles but may struggle with ultra-fine silt.

High-Efficiency Sand Washing & Recycling Machine (Combined System)

Working principle: Combines washing, dewatering, and fine-material recovery in one system.

Applied material: Ultra-clean sand production with minimal loss of fine particles.

Cleaning efficiency: The cleanest output due to multiple filtration stages (hydrocyclones, vibrating screens).

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.