Basalt is the best material in the stone used for repairing roads, railways and airport runways. It has the advantages of strong compressive resistance, low crushing value and strong corrosion resistance. Basalt is recognized internationally as the best cornerstone for the development of railway transportation and highway transportation.

Basalt processed by crusher can produce coarse aggregate and fine aggregate. So what kind of crusher machine is usually needed for a 300 t/h basalt crushing production line?

✤ The comparison of basalt particles after processing

Mechanism sand made from basalt can be divided into two types, coarse aggregate and fine aggregate.

1. Coarse aggregate

When the stone particle size is above 4.75mm, we divide it into coarse aggregate, such as 12 stones (stone particle size between 10-20mm), 13 stones (stone particle size between 16-31.5mm), 24 stones (stone particle size between 10-15mm), etc.

2. Fine aggregate

When the stone particle size is below 4.75mm, we divide it into fine aggregate, usually called sand, such as coarse sand (particle size is greater than 0.5mm), medium sand (particle size is 0.5-0.35mm), fine sand (particle size is 0.35-0.25mm), ultra-fine sand (particle size is less than 0.25mm), etc.

✤ What are the basalt crusher machines?

1. Cone crusher

Cone crusher is the representative crusher equipment of crushing hard materials, there are many kinds, which is more suitable for use in the production of coarse aggregate.

Single cylinder hydraulic cone crusher, medium crushing type, can produce materials below 19-41mm; Finely crushing type, can produce materials below 4-25mm.

Multi-cylinder hydraulic cone crusher can produce material below 5-51mm.

2. Vertical shaft impact sand making machine

Vertical shaft impact sand making machine is specialized for sand making, using the working principle of “stone beat stone” and “stone beat iron” to complete the crushing process, its sand production efficiency is high, the product grain shape is good, the maximum output of 200 tons per hour.

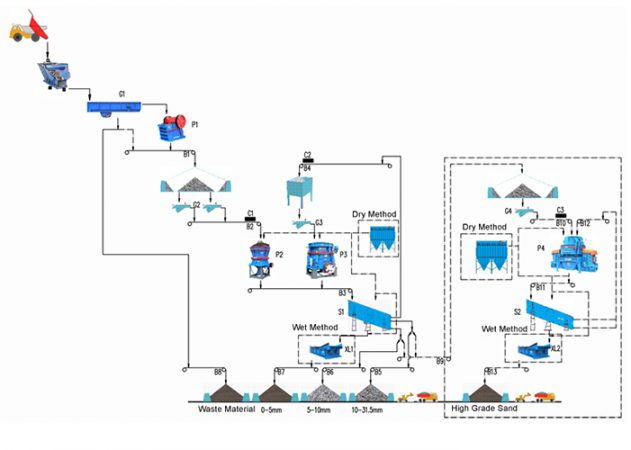

✤ How to configure the basalt crushing production line?

Basalt crushing production line should include the following equipment: raw material bin, vibrating feeder, jaw crusher, conveyor, vibrating screen, cone crusher, sand making machine.