The processing technology of sand and stone aggregate has become increasingly sophisticated with the development of the sand and stone industry, leading to a growing demand for higher quality aggregates in the infrastructure market. The utilization of gravel crusher machine is essential, as it not only facilitates the crushing of large stone pieces but also possesses the capability to shape them. Consequently, the crushed stones exhibit superior quality, high grading, and commendable market value. This article aims to provide comprehensive insights into the various types, models, and prices of gravel crushers.

The gravel crusher machine has full range of types and models for selection. Commonly found stone crusher machine in the market include impact crushers, mobile crushers, and vertical shaft impact crushers. Users can select based on processing capacity, material type, site requirements, discharge specifications, and other specific needs.

Impact crusher

Feeding size: ≤1400mm, Production capacity: 50-1200 t/h

The impact crusher adopts the principle of impact crushing. The stone repeatedly impacts the lining plate to achieve complete crushing, which is better than other extrusion crushers. Additionally, it has the ability to shape stones, making it suitable for processing medium-hardness materials such as bluestone, coal gangue, dolomite, and construction waste. The lining board is made of highly wear-resistant materials, ensuring its durability.

Vertical shaft impact crusher (VSI)

Feeding size: ≤60mm, Production capacity: 16-725 t/h

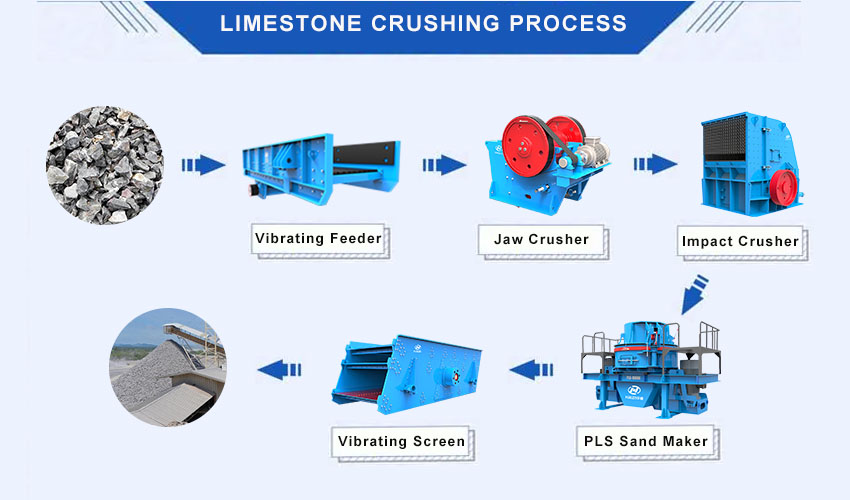

The vertical shaft impact crusher utilizes the combined principles of “stone-beat-stone” and “stone-beat-iron”. The stone-beat-iron enhances output capacity, while the stone-beat-stone improves the grain shape of the final product. With this dual-functioning machine, limestone raw materials can be transformed into high-quality mechanical sand.

Mobile crusher plant

The above described gravel crushers can be configured in a mobile form, namely, mobile crusher plants include mobile impact crushers, mobile gravel sand making machines, etc., and each type is available in three chassis forms (tracks, tires, and modular).

The mobile crusher plant has the advantages of high operating efficiency, environmental friendliness, energy conservation, safety and stability. Additionally, it offers the flexibility to relocate production in order to address various construction-related environmental issues.

How much is the price of gravel crusher machine?

The price of gravel crusher machine varies due to the presence of multiple sellers, direct sales from manufacturers, intermediaries, and the availability of second-hand equipment. Even if they are of the same model, different manufacturers may have slight variations in manufacturing processes, production quality, feed granularity, motor power, and other technical parameters.

How much does the gravel crusher machine cost? Feel free to contact our customer service for a complimentary quotation. Luoyang Dahua, a renowned crusher manufacturer, offers competitive factory prices and ensures prompt delivery. We provide impeccable services and guarantee reliable quality assurance. Our dedicated equipment managers are available to provide detailed introductions.