Recently, some customers have been inquiring about the differences between high pressure roller mills and roll crushers, as well as how to choose. Here, Luoyang Dahua from the equipment working principle, characteristics, applicable materials and other aspects to answer your questions.

The working principle

1. The high pressure roller mill consists of rollers, pressure adjustment devices, transmission devices, pressure holding devices, and retracting devices. Its working principle is to compress the material into a cake using high pressure and then finely crushing it to enhance crushing efficiency. Additionally, the gap between the rolls can be adjusted based on the material’s properties.

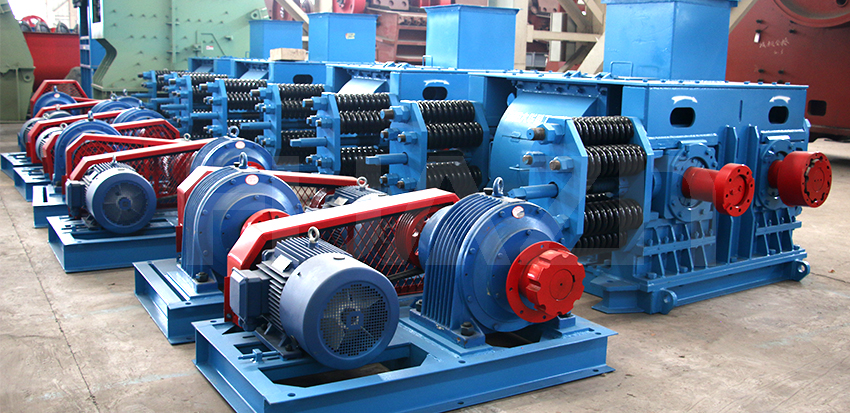

2. The roller crusher is a traditional mechanical crushing equipment, which is consisted of two working rollers, a housing, a transmission device, and a regulating device. The motor drives the rollers to rotate through the transmission device, allowing the interaction between the two rollers to grind the material with low pressure.

Equipment characteristics

1. The high pressure roller mill is a modern grinding equipment, its main characteristics are high pressure, high efficiency, and low energy consumption.

2. The roller crusher is grinding equipment with simple structure, low cost and easy maintenance.

Applicable materials

1. The high pressure roller mill is suitable for materials with high hardness. It is widely used for the material crushing and fine grinding, such as high pressure pulverized coal and cement grinding, etc.

2. The roller crusher is suitable for grinding materials of medium hardness, making it ideal for preliminary crushing and achieving a medium fineness. It can be used in various industries such as construction waste treatment, mining, and chemical industry.

Through the introduction of this article, we can see that there are some differences between the high-pressure roller mill and the roller crusher in the working principle and application scope. Therefore, when selecting a suitable crusher, it is important to choose a model according to the specific needs and material characteristics in order to achieve optimal crushing efficiency and effectiveness.