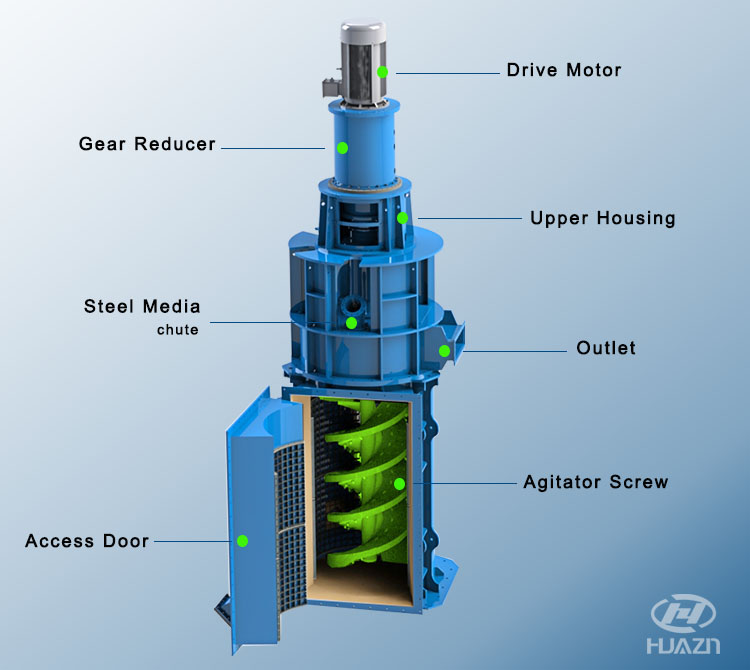

At its core, a vertical tower mill is a stirred grinding mill. Unlike a traditional ball mill that relies on tumbling rods or balls in a horizontal drum, the vertical tower mill uses a vertical screw (or auger) to actively stir a charge of grinding media within a stationary mill shell.

How the vertical tower mill works:

Feed Entry: The raw material, often pre-crushed to a few millimeters, is fed into the bottom of the mill.

Grinding Zone: As the material moves upward, a centrally mounted screw rotates, vigorously agitating a charge of small grinding media (such as steel or ceramic balls). This creates a high-density, intense grinding environment where particles are crushed and ground through a combination of attrition and impact.

Classification: The ground material reaches the top of the mill, where a simple yet effective internal classification occurs. Heavier, coarser particles are rejected and fall back down for further grinding.

Product Discharge: Finer, lighter particles are carried out of the mill by the slurry or air stream (depending on whether it’s a wet or dry process) as the finished product.

This closed, efficient system of vertical tower mill allows for precise control over the product size with significantly less energy waste in the form of heat and noise compared to traditional mills.

Luoyang Dahua HMT series vertical tower mill is designed to operate at low speed and handle heavy loads, ensuring high reliability and a long lifespan. It allows for quick adjustments in slurry concentration and product particle size within a certain range. Additionally, it exhibits strong adaptability to different hardness levels, viscosities, and grindabilities, greatly enhancing its ability to process various materials. This not only effectively reduces installation and usage costs for customers but also significantly improves the selection process. The mine plant not only offers benefits, but also boasts a small footprint, a simple equipment base, and convenient installation and maintenance.