Dolomite belongs to carbonate minerals, which are mostly massive and granular aggregates. The crystal structure is similar to that of calcite. Mohs hardness is about 3.6-4. Dolomite is widely used in building materials, ceramics, glass and refractory materials, chemical industry, agriculture, and other fields.

☛ Can dolomite be used as building stone?

Dolomite is a common building material, after crushing, screening and other processing, can be used as building stone for road foundation material, concrete, asphalt aggregate, railway ballast and gravel or filler.

☛ What crusher machine can be used for dolomite crushing?

There are many options for dolomite crusher, such as jaw crusher, impact crusher, and hammer crusher, etc. The specific introduction is as follows:

✤ Jaw stone crusher

The prominent advantages of jaw stone crusher are large feed mouth, strong wear resistance, large production capacity, and relatively stable operation. Hourly production can reach 1000 tons, feed particle size between 1-1200mm. Jaw stone crusher is suitable for the rough crushing of hard, medium, soft and other large stone, which is a common crusher machine in stone processing line.

✤ Impact crusher

Impact crusher is mainly used for the processing of fine material, often with jaw crusher. This crusher is good at the processing of medium and below hardness of materials. impact crusher adopts the principle of impact crushing, the discharge grain type is more cubic, less needle flake content.

✤ Hammer crusher

The hammer crusher can directly crush the material with the particle size of 600-1800 mm to below 35 mm, the feeding particle size is large, and the discharging particle size is small. It can achieve one-stage crushing instead of three step crushing, completely realize the low cost, and suitable for users with limited investment budget.

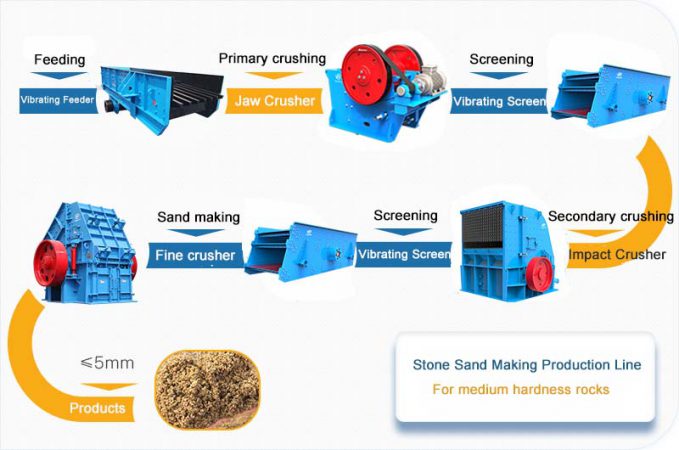

☛ Processing flow of dolomite production line (Solution)

Stage 1: dolomite – coarse crushing

Large pieces of dolomite are sent to the jaw crusher for coarse crushing by the feeder after blasting treatment or excavation. The semi-finished materials after crushing are 95-300mm.

Stage 2: dolomite – medium fine crushing

After being coarsely crushed by the jaw crusher, dolomite is sent to the impact crusher through the conveyor belt for secondary medium and fine crushing processing, and the mixed aggregate with particle size less than 40mm is obtained.

Stage 3: dolomite – screening

The material obtained from medium and fine crushing is transported to the subsequent screening workshop by belt machine for classification and screening, and the large particle material is returned to the impact crusher through belt machine for circulation crushing.