Jaw crusher, cone crusher and impact crusher are the common used stone crusher machine in mining industry. Why they are so popular? What’s the working principle?

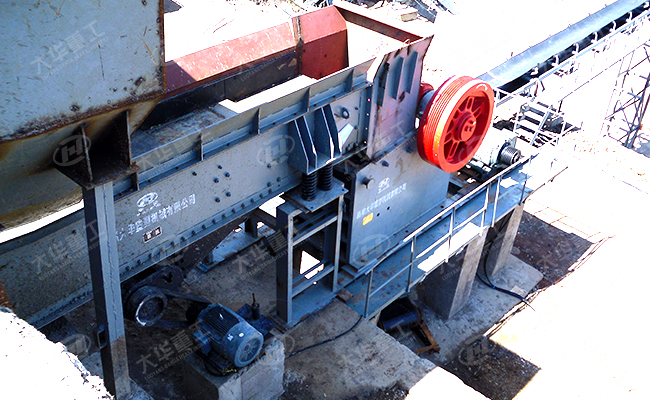

Jaw crusher working principle: when working, the motor drives the eccentric shaft rotation through the belt pulley, so that the moving jaw close to and leave from the fixed jaw. The material is crushed from large to small by extrusion, rubbing, and grinding, and then gradually falling, until discharged from the discharge port.

Cone crusher working principle: In the working process of cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone rotates and swings under the force of the eccentric sleeve. The material is broken by the multiple extrusion and impact of the moving cone and the static cone. When the moving cone leaves the section, the part has been broken to the required particle size of the material falls under the action of its own gravity, discharged from the bottom of the cone crusher.

Impact crusher working principle: Impact crusher is a kind of crushing machinery which uses impact energy to break materials. When the machine is working, driven by the motor, the rotor rotates at a high speed. When the material enters the plate hammer action area, it is smashed by the plate hammer on the rotor, and then it is thrown to the impact device to be broken again, and then it springs back to the plate hammer from the impact plate to be broken again. This process is repeated, until the material is broken to the required size, discharged from the discharge port.

After we understand the working principle of the crusher, how to choose it? The selection of crusher needs to consider a variety of factors, such as raw material hardness, crusher machine production capacity, material feeding and discharging size, local site conditions, financial status, etc. Below, I briefly summarize the selection points of these three types of crusher:

Jaw crusher: It can be used to break various materials, such as pebbles, limestone, quartz, iron ore and other minerals. Jaw crusher crushing ratio is very large, because its structure is very simple, the replacement of wearing parts is particularly convenient, cost-effective, it is popular with the majority of users.

Cone crusher: it is mainly suitable for crushing medium and hard materials, such as granite. Cone crusher can be divided into single cylinder, multi-cylinder, full hydraulic, compound and other models, users can choose according to their own needs.

Impact crusher: It is generally used to break relatively fine materials. Used for secondary crushing, the broken product is a cube, and the particle size is uniform, the price is much cheaper than the cone crusher.

In short, users still need to choose according to their own needs, if you don’t know how to choose it, please visit www.lydhchina.com to know more, or contact us at any time. Email: lydhchina@huazn.com, Whatsapp: 0086 13938852499, Facebook.