When configuring the equipment of stone crushing production line, users can choose different crushing equipment according to the different hardness of stone, and can also be broken according to the product size requirements of different crushing or multiple crushing solution. Here, Luoyang Dahua shares with you a 300 tph cobble crushing production line configuration scheme.

300 tph cobble crushing production line

Processed material: cobble

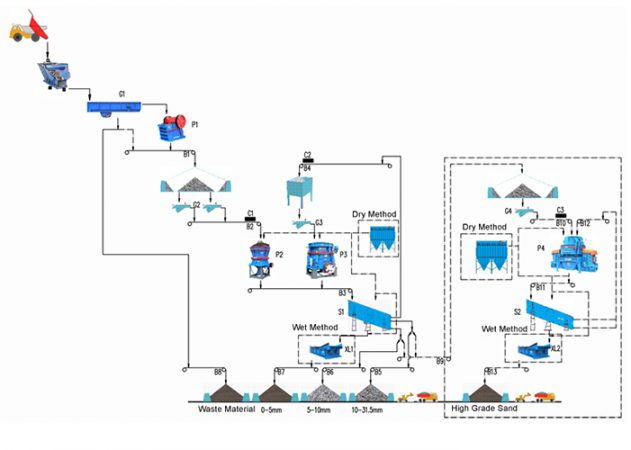

Equipment configuration: vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor.

1. First stage, primary crushing process: cobblestone through the raw material bin into the vibration feeder, and then the vibration feeder will evenly transport the cobblestone to the jaw crusher in the first simple primary crushing process.

2. Secondary stage (medium, fine) crushing process: The materials through primary crushing process are transported into the impact crusher through the belt conveyor for secondary (medium, fine) crushing process.

3. Screening and grading: The processed stone is screened through the vibrating screen system for finished products. Cobblestone with standard particle size is sent out by belt conveyor.

4. Circular crushing: Qualified processed raw materials are the finished products we need, the unqualified raw materials will be returned to the crushing chamber for further crushing, and can be broken repeatedly until the finished product requirements are reached.

Stone crushing production line advantages

1. High degree of mechanization: The equipment of the production line is well coordinated with each other, which does not need to consume too much labor cost. The machine has stable performance and high production efficiency, which can produce high-quality finished aggregate for the majority of investment users and increase users’ income.

2. The wide use rang: Stone crushing production line can process coarse, medium and fine stones crushing respectively, and the finished aggregate with more beautiful grain shape and more uniform particle size, so as to improve the quality of finished stone, and provide high quality stone for highway, railway, water conservancy, concrete mixing station and other industries.