Quartz sand is widely utilized in public construction, glass, ceramics, metallurgy, and chemical industry. It is quartz particles produced by quartz stone through the production of crushing and sand making. How to design a 200 t/h quartz sand crushing production line? Below is a comprehensive overview of the entire process flow of quartz sand production.

Process flow of 200 t/h quartz sand production

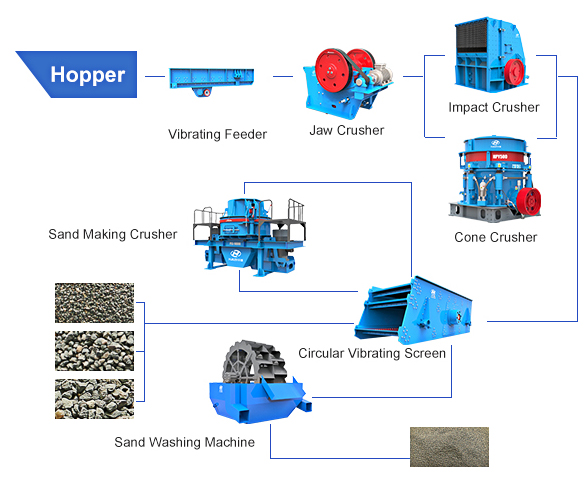

The process flow of quartz sand production line is feeding, crushing, sand making, screening, and sand washing. Currently, there are many types of equipment for processing quartz stone on the market. The main component of quartz stone is silicon dioxide, a non-mineral material characterized by high hardness, wear resistance, and chemical stability. Therefore, considering these physical and chemical properties, it is recommend to use jaw crusher, cone crusher, and sand making machine for efficient and reliable processing.

A complete process flow for 200 t/h quartz sand production

Raw material → vibrating feeder → jaw crusher → cone crusher → sand making machine → vibrating screen → sand washing machine → finished products.

Feeding: Quartz stone is sent into the vibrating feeder by dump truck, and then evenly and continuously fed to the coarse crushing equipment, and the waste material and soil are screened.

Coarse crushing: Typically, a suitable location for coarse crushing is carefully selected and set up close to the quarry to minimize the transportation distance of raw materials. Large materials are initially crushed using a jaw crusher, which features a deep crushing chamber and a design free of dead zones—ensuring smooth operation without the risk of material blockage.

Medium crushing: The material is then gently transported via conveyor to the cone crusher for medium and fine crushing. This secondary crushing process can also produce aggregate from 10-31.5 mm.

Sand making: For sand production, after crushing, the material, typically under 55 mm is fed into the sand making machine, where it is further processed to create high-quality quartz sand with a consistent size of 0.25–0.5 mm.

Screening: It enters the vibrating screen through the conveyor, with 4 layers of screens that can screen sand with 3 different particle sizes at one time.

Sand washing: The sand washing machine is used to separate soil, impurities, and sand and gravel, effectively purifying the material and precisely controlling the stone powder content. After passing through the dewatering screen, clean, high-quality manufactured sand is produced.

How much is a complete set of 200 t/h quartz sand production line?

The price of a complete set of quartz sand production line typically changes from tens of thousands and hundreds of thousands of US dollars. This is related to the machine selection, design scheme. Moreover, there are many manufacturers offer such equipment, difference in material, processing technologies, and production quality contribute to the variability in quotations.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.