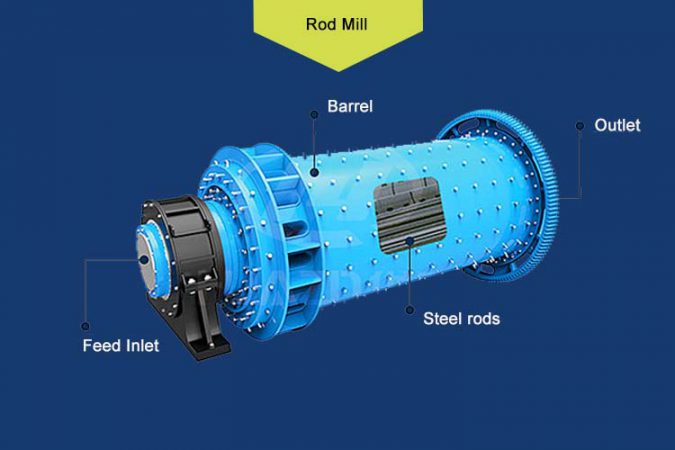

Rod mill is a reliable and efficient grinding machine, often referred to as “dry or wet grinding rod mill”. Its versatility allows it to handle a wide range of materials, from metallic ores to limestone and even industrial minerals. If you’re considering this crucial piece of equipment for your operation, understanding its price factors and key technical parameters is essential.

How much does a rod mill cost?

The price of rod mill is ranging from as low as $10,000 for a small, standardized laboratory model to well over $1,000,000 for a massive, custom-designed industrial unit. This wide disparity is due to several critical factors:

Processing Capacity (TPH): The most significant cost factor. A mill designed to process 10 tons per hour (TPH) will be exponentially cheaper than one built for 500 TPH.

Customization and Features: Standard models are more affordable. Customization like special liners, advanced control systems, or specific motor requirements add to the cost.

Manufacturer and Brand: Established, high-repute brands often command a premium due to their proven reliability, after-sales service, and engineering excellence.

Geographical Location: Shipping, import duties, and local market competition can significantly influence the final price.

Material of Construction: The quality of steel, the type of liner (e.g., manganese steel, rubber), and other wear-resistant materials impact both initial cost and long-term maintenance expenses.

Key technical parameters and configuration

When selecting a rod mill, you must analyze its technical data sheet. Here are the critical parameters to consider:

| Model | Barrel Size (mm) | Barrel Volume(m3) | Rod Load (t) | Speed(r/min) | Power | Outlet Size | Capacity |

| Dia. × Length | (mm) | (t/h) | |||||

| GMBZ1535 | φ1500×3500 | 5.9 | 8 | 23 | 90 | 2.5-0.2 | 15-6 |

| GMBZ1835 | φ1800×3500 | 7.9 | 13 | 22.8 | 160 | 2.5-0.2 | 25-10 |

| GMBZ2130 | φ2100×3000 | 9.2 | 17 | 20.9 | 185 | 2.5-0.2 | 32-13 |

| GMBZ2136 | φ2100×3600 | 11.0 | 18 | 20.9 | 210 | 5-0.8 | 38-15 |

| GMBZ2140 | φ2100×4000 | 12.2 | 19 | 20.9 | 220 | 5-0.8 | 43-17 |

| GMBZ2145 | φ2100×4500 | 13.8 | 20 | 20.9 | 250 | 5-0.8 | 49-20 |

| GMBZ2442 | φ2400×4200 | 17 | 21 | 19 | 355 | 5-0.8 | 58-24 |

| GMBZ2445 | φ2400×4500 | 18.2 | 23 | 19 | 355 | 5-0.8 | 63-27 |

| GMBZ2736 | φ2700×3600 | 18.4 | 24 | 17.5 | 400 | 5-0.8 | 82-33 |

| GMBZ2745 | φ2700×4500 | 22.4 | 27 | 17.5 | 500 | 5-0.8 | 90-36 |

| GMBZ3050 | φ3000×5000 | 31.9 | 46 | 17.3 | 630 | 5-0.8 | 140-50 |

| GMBZ3250 | φ3200×5000 | 35.7 | 52 | 16.37 | 800 | 5-0.8 | 185-70 |

| GMBZ3460 | φ3400×6000 | 49.2 | 72 | 15.53 | 1120 | 5-0.8 | 220-85 |

| GMBZ3660 | φ3600×6000 | 55.1 | 80 | 14.98 | 1250 | 5-0.8 | 260-105 |

| GMBZ4060 | φ4000×6000 | 69.8 | 102 | 13.53 | 1600 | 5-0.8 | 310-130 |

Before making a decision, carefully evaluate your production needs, feed characteristics, and desired product specifications. Request detailed quotations from multiple manufacturers, ensuring they include not only the machine price but also shipping, installation, and commissioning costs. By thoroughly understanding both the price factors and technical configurations, you can select the rod mill that delivers optimal performance and return on investment for your specific application.