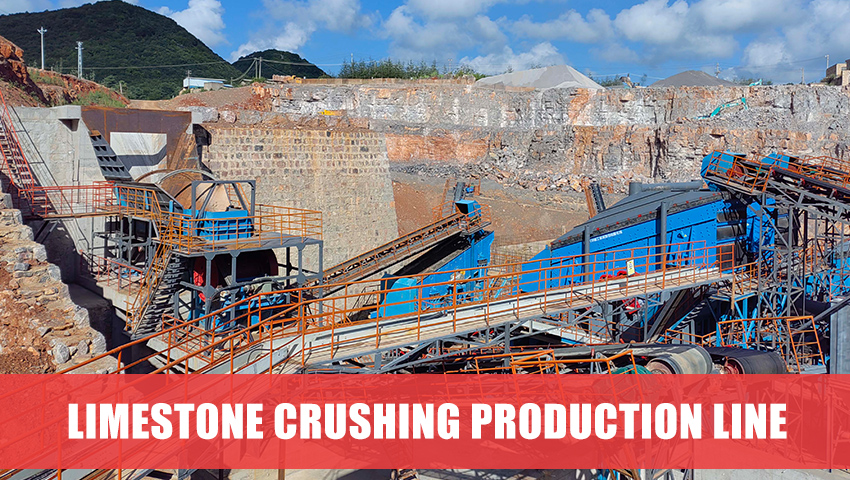

A 500 TPH sand making production line is a large-scale crushing and sand-making system designed to produce high-quality manufactured sand and aggregates for construction, road building, and concrete production. This article provides a detailed configuration plan and cost analysis for setting up such a production line.

Production Line Configuration

A 500 TPH sand making production line should include primary crushing, secondary crushing, sand making, screening, and material conveying systems. Below is a typical configuration:

- Primary Crushing Stage (Jaw Crusher)

Capacity: 500 TPH

Input Size: ≤1000mm

Output Size: ≤300mm

- Secondary Crushing Stage (Cone Crusher or Impact Crusher)

Capacity: 500 TPH

Input Size: ≤300mm

Output Size: ≤50mm

- Sand Making Stage (Vertical Shaft Impact Crusher)

Capacity: 300-350 TPH

Input Size: ≤50mm

Output Size: 0-5mm (adjustable)

- Screening Stage (Vibrating Screens)

Equipment: Multi-layer vibrating screens

Capacity: 500 TPH

- Sand Washing Stage (Bucket Wheel Sand Washing Machine)

Capacity: 200-300 TPH

- Conveying System (Belt Conveyors)

Equipment: Multiple belt conveyors (width: 800-1400mm)

What is the price of 500 tph sand making production line?

For the cost of 500 tph sand making production line, it depends on the actual configuration. The price varies from different manufacturers and machine model. Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.