Purchasing a jaw crusher is a significant investment for any quarry, mine, or recycling operation. It’s the heart of the primary crushing stage, and its performance dictates the efficiency of the entire downstream process. What should be pay attention to?

Q1: “What material is this jaw crusher designed for, granite, basalt, limestone, or construction waste?”

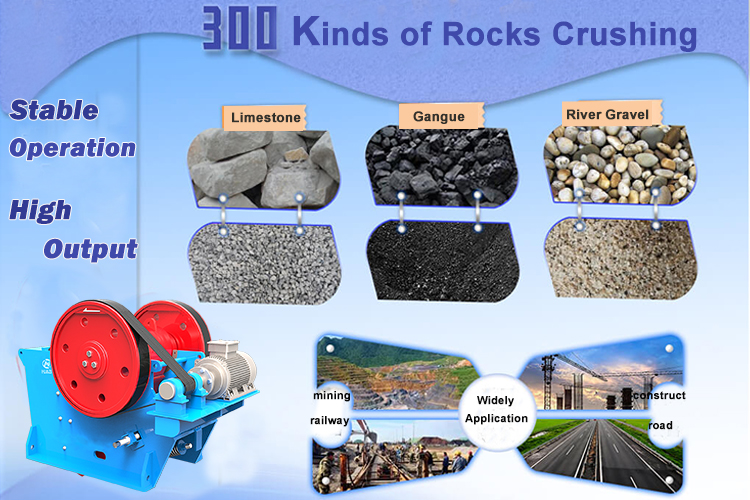

Answer: Modern jaw crushers are designed for a wide range of materials. The key differentiator is the wear parts and, sometimes, the crusher’s design kinematics.

For hard, abrasive rocks (Granite, Basalt, and Quartzite): We recommend crushers (JC jaw crusher) with a robust frame, high-quality cast steel jaw plates (often with a Mn18 or equivalent grade), and an optimized crushing chamber geometry for high pressure. The eccentric shaft and bearings must be oversized for the immense stress.

For softer, less abrasive rocks (Limestone, Dolomite): Efficiency and output become the priority. Standard high manganese steel (Mn14) jaws are often sufficient, and we can focus on designs that maximize capacity and produce a well-graded product.

For recycled materials (Concrete, Asphalt, C&D Waste): Here, protection from uncrushable items like rebar is crucial. We suggest models (PEY jaw crusher) with a hydraulic toggle release system that allows the crusher to open and eject tramp metal automatically, minimizing downtime and risk of severe damage.

Q2: “What is the maximum feed size and the adjustment range for the final product? How do I control the output size?”

Answer:

Maximum Feed Size: This is determined by the crusher’s feed opening (e.g., 1200mm x 800mm). The rule is that the largest block should be no more than 80-90% of the feed opening’s width. We will help you calculate this based on your primary blast or load size.

Product Size Adjustment: The discharge opening, or CSS (Closed Side Setting), is mechanically adjusted. Most crushers use shim plates or hydraulic pistons behind the toggle plate to move the jaw. The range is model-specific (e.g., from 75mm to 200mm). A finer setting gives a smaller product but reduces throughput; a wider setting increases capacity but yields a coarser product. We provide clear guidance on this trade-off.

Q3: “What is the realistic hourly capacity (in tons per hour) for my material? What factors can reduce this number?”

Answer: The catalog capacity is based on lab conditions with optimal, continuous feed of a defined material. Real-world throughput can vary by ±15-20%. Key influencing factors include:

Material Characteristics: Hardness, abrasiveness, density, and moisture content (sticky material can cause clogging).

Feed Gradation: A mix of sizes feeds better than all large blocks. Pre-screening (“scalping”) fines can significantly boost capacity.

Feed Method: Consistent, even feeding across the entire width of the crusher is critical. A vibrating grizzly feeder is highly recommended over direct dump from an excavator.

CSS Setting: As mentioned, a smaller CSS reduces capacity.

Q4: “What is the expected service life of the jaw plates and other wear parts? How to replace?”

Answer: This is the core of operating cost.

Service life: For hard abrasive granite, manganese jaw plates may last 60,000 to 90,000 tons. For limestone, this can exceed 150,000 tons. Factors include material, CSS, and jaw plate profile (straight, curved, etc.).

Reversible Jaw Plates: Extend life by using both ends.

Wedge or Bolt-on Systems: Allow for relatively fast replacement.

Accessible Design: Ample room for mechanics and tools.

We provide estimated wear life calculations and detailed change-out procedures and tool lists.

Q5: “What does daily and periodic maintenance involve?”

Daily: Visual checks for loose bolts, monitor abnormal noise/vibration, check grease levels and bearing temperatures.

Weekly/Monthly: Inspect wear part thickness, tighten key fasteners, check toggle plate and seats. We provide a clear, customized maintenance schedule and logbook.

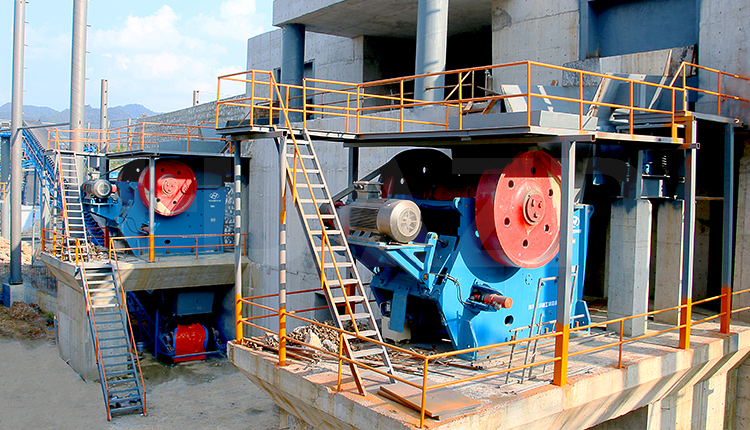

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.