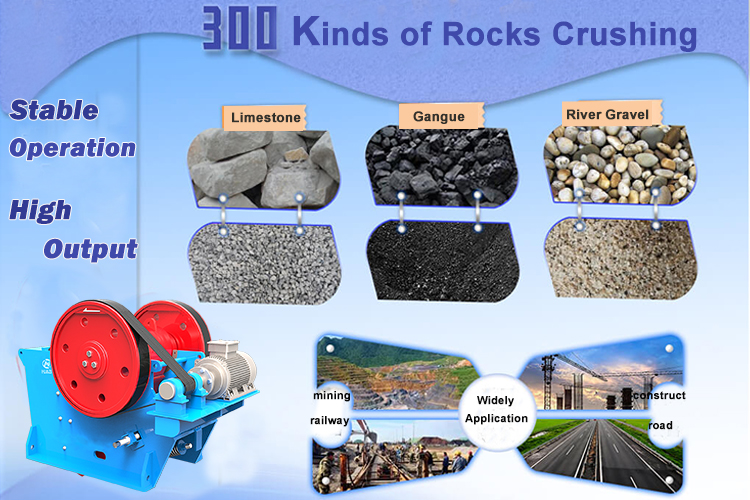

JC series jaw crushers with unique structure and superior performance, it is a type of preferable equipment for crushing various hard and highly abrasive rocks and minerals. Its production capacity ranges from 50 to 2000 tons per hour, which can meet the production demands of different capacities. It offers a wider range of choices and stronger applicability.

Influencing factors of production capacity

Raw material characteristics: The hardness, moisture content and silicon content of the material will all affect the crushing efficiency and output.

Process requirements: The finer the particle size of the finished product is required, the longer the crushing time will be and the lower the output will be.

When determining whether a model of a crusher is appropriate, it is necessary to fully understand the parameters of the crusher. However, the definitions of each manufacturer are not the same. With continuous technological innovation, the values may also changes. Please pay attention and make a choice based on the overall situation.

Basic specifications

Feed opening: Maximum 2000×1500 mm.

Feed particle size: 430-1300 mm

Discharge opening: 40-300 mm

Performance parameters

Processing capacity: The production capacity ranges from 50 to 2,000 tons per hour, which is specifically affected by the characteristics of the materials and the configuration of the production line.

Motor power: 75-400 kw, equipped with an 8-pole motor, providing more abundant power and effectively reducing energy consumption.

| Model | Feed Opening Size(mm) | Max. Feed Size(mm) | Discharge Opening Size(mm)/Capacity(t/h) | Power(kw) | ||||||||||||||

| 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 | ||||

| JC80 | 800×510 | 430 | 50 | 55 | 80 | 90 | 110 | 120 | 135 | 170 | 200 | 240 | 75 | |||||

| 70 | 85 | 100 | 125 | 145 | 170 | 185 | 240 | 280 | 330 | |||||||||

| JC90 | 910×630 | 500 | 80 | 100 | 120 | 140 | 160 | 180 | 210 | 260 | 300 | 90 | ||||||

| 110 | 120 | 140 | 170 | 200 | 220 | 280 | 330 | 360 | ||||||||||

| JC100 | 1000×760 | 640 | 130 | 160 | 180 | 200 | 235 | 280 | 330 | 390 | 110 | |||||||

| 190 | 200 | 225 | 250 | 310 | 370 | 420 | 520 | |||||||||||

| JC110 | 1100×850 | 720 | 180 | 200 | 220 | 245 | 300 | 350 | 400 | 460 | 110 | |||||||

| 240 | 265 | 295 | 320 | 385 | 455 | 520 | 590 | |||||||||||

| JC125 | 1250×950 | 810 | 270 | 325 | 385 | 445 | 500 | 560 | 620 | 160 | ||||||||

| 360 | 430 | 505 | 580 | 650 | 725 | 800 | ||||||||||||

| JC130 | 1250×110 | 940 | 330 | 360 | 440 | 500 | 555 | 600 | 670 | 730 | 185 | |||||||

| 400 | 450 | 530 | 610 | 700 | 780 | 850 | 900 | |||||||||||

| JC140 | 1400×1070 | 910 | 380 | 465 | 530 | 580 | 650 | 710 | 760 | 200 | ||||||||

| 470 | 555 | 640 | 725 | 815 | 900 | 985 | ||||||||||||

| JC160 | 1600×1200 | 1020 | 490 | 550 | 635 | 710 | 780 | 855 | 930 | 250 | ||||||||

| 640 | 730 | 825 | 920 | 1010 | 1105 | 1200 | ||||||||||||

| JC1613 | 1600×1300 | 1110 | 530 | 600 | 680 | 750 | 850 | 910 | 960 | 315 | ||||||||

| 680 | 760 | 870 | 960 | 1100 | 1200 | 1300 | ||||||||||||

| JC2012 | 2000×1200 | 1020 | 600 | 670 | 750 | 830 | 950 | 1050 | 1150 | 355 | ||||||||

| 730 | 900 | 1030 | 1150 | 1220 | 1300 | 1400 | ||||||||||||

| JC180 | 1800×1500 | 1300 | 700 | 810 | 930 | 1000 | 1080 | 1200 | 355 | |||||||||

| 1000 | 1150 | 1300 | 1450 | 1600 | 1800 | |||||||||||||

| JC200 | 2000×1500 | 1300 | 750 | 860 | 960 | 1050 | 1150 | 1300 | 400 | |||||||||

| 1100 | 1280 | 1500 | 1650 | 1850 | 2000 | |||||||||||||

Luoyang Dahua JC jaw crusher structure features

1. Solid structure

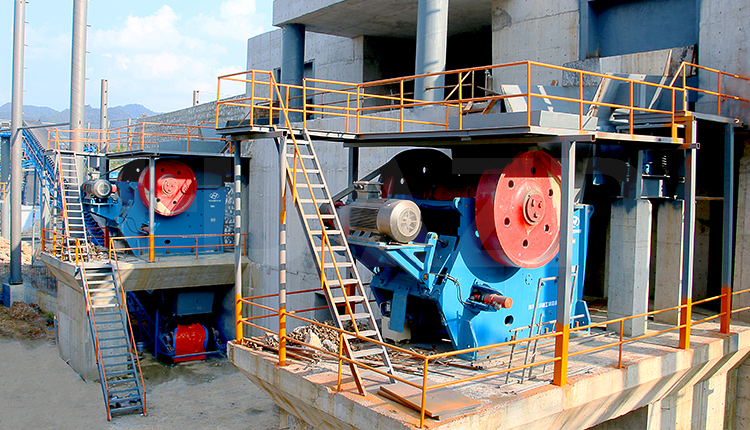

The machine frames can be classified into two types: the welded-type machine frame generally used for small and medium models, and the split-type machine frame generally used for large models, especially suitable for the installation in underground mines.

2. Optimal design of crushing chamber

The V-type symmetrical design of the crushing chamber, tight nip angle and long stroke, making the machine has lower energy consumption, better processing capacity and excellent crushing performance.

3. Swing jaw assembly

The swing jaw assembly consists of the forged eccentric shaft, high-duty rolling bearings and the swing jaw optimized by FEM analysis, which ensure the impact resistance and stability of swing jaw assembly. By using the labyrinth seal and centralized lubrication system, there ensure no pollution to the bearing grease and convenient lubrication, also ensure long operating time and good stability.

4. Protector plate of swing jaw

The protector plate installed on the swing jaw reduces the impact force from materials, which effectively protect the swing jaw and bearings inside

5. Quick and convenient CSS adjustment

The JC Series Jaw Crusher applies mechanical or hydraulic discharge adjusting device for CSS. Compared with gasket adjustment (refer to mechanical device), its double wedge adjustment (refer to hydraulic device) is simple, safe and fast. It can also reduce the downtime.

6. Rod spring or hydraulic cylinder

The rod spring applies advanced friction reducing devices. It can make easy and quick adjustment.

7. Internal bearing house

The integral casting bearing structure ensures the perfect match with the main frame, which avoids the unnecessary radial load to the bearings during the fastening process of integral bearing house.

8. Integrated motor design

The integrated design of the motor base together with the main frame not only will save the installation space of jaw crusher, but also reduce the length of the V-belt.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.