Is an impact crusher suitable for crushing limestone? The answer is yes. Not only is it suitable, but the impact crusher is often considered one of the most efficient and optimal choices for processing this sedimentary rock.

How an Impact Crusher Works

An impact crusher utilizes the principle of high-speed impact to break materials. Inside the machine, rotors fitted with blow bars (hammers) rotate at high velocities. The fed limestone rocks are struck by these blow bars and hurled against the impact plates on the crusher’s walls. This process subjects the material to intense kinetic energy, causing it to fracture along its natural cleavage planes. The repeated impacts and collisions between the material and the liners, as well as between the rocks themselves, result in a well-controlled, cubical end product.

Why Limestone and Impact Crushers Are a Perfect Match

Ideal Material Characteristics: Limestone is a medium to low hardness rock (typically 3-4 on the Mohs scale) and is not excessively abrasive. Impact crushers excel at processing materials of this nature. They can achieve high reduction ratios in a single stage, effectively breaking large limestone boulders down to the desired size.

Superior Product Shape: One of the standout advantages of using an impact crusher for limestone is the excellent grain shape it produces. The impacting action creates more cubical, evenly graded particles with fewer elongated or flaky fragments. This is a critical requirement for high-quality concrete aggregate, road stone, and construction fill, where proper interlocking and compaction are essential.

High Efficiency and Productivity: Modern impact crushers are designed for high throughput. They offer large feed openings and robust rotors capable of handling sizable limestone blocks. The adjustable settings for the gap between the rotor and impact aprons allow for precise control over the final product size without significant speed changes.

Versatility in Applications: An impact crusher is not limited to just primary crushing. It can be perfectly deployed as a secondary crusher following a jaw crusher for further refinement of limestone. Furthermore, many impact crushers feature hydraulic adjustment systems and interchangeable wear parts, making them adaptable for producing various product sizes to meet different market specifications.

Economic Operation: While wear parts (blow bars and impact plates) do require periodic replacement, the relatively low abrasiveness of limestone compared to granite or basalt leads to acceptable wear costs. The energy efficiency, high output, and premium product quality often translate to a favorable cost-benefit ratio for limestone processing plants.

Practical Applications

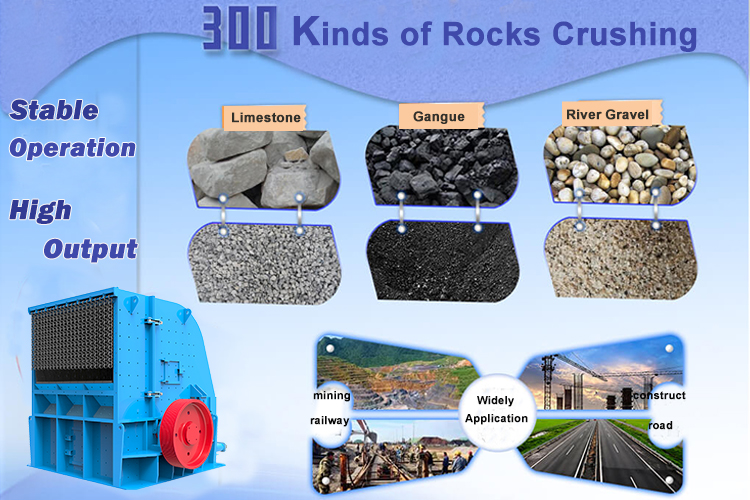

Impact crushers are widely used in limestone quarries and cement plants around the world. They produce aggregates for:

Concrete and asphalt production

Road base and sub-base layers

Railroad ballast

Raw material feed for cement kilns

In summary, the impact crusher is not merely “capable” of crushing limestone; it is a highly recommended and technologically advanced solution for this purpose. Its ability to deliver a cubical, in-spec product at high tonnage rates with operational flexibility makes it a cornerstone of modern limestone processing circuits. For any operation focused on producing high-quality limestone aggregates, the impact crusher undoubtedly deserves a primary position in the equipment selection process.