The roller crusher is used for the crushing of limestone, coal, clay, and other minerals. Unlike jaw or cone crushers, roller crushers apply compressive force via two rotating cylindrical rollers, making them ideal for producing finer product sizes with minimal fines. However, with various models and specifications on the market, making an informed choice requires careful evaluation.

1. Operational Requirements & Material Characteristics

Material Properties: What is the type, hardness (e.g., Mohs scale), abrasiveness, moisture content, and feed size of the raw stone? Wet, sticky materials can clog a standard crusher, requiring special design features.

Required Feed Size and Output Size: What is the maximum size of stone you will feed into the crusher (input)? What is your target product size or size range (output)? This directly determines the needed roller diameter, width, and gap setting.

Desired Capacity (TPH): What is your required throughput in tons per hour? This dictates the power, size, and model of the crusher. Be realistic about both average and peak demands.

2. Technical Specifications & Design

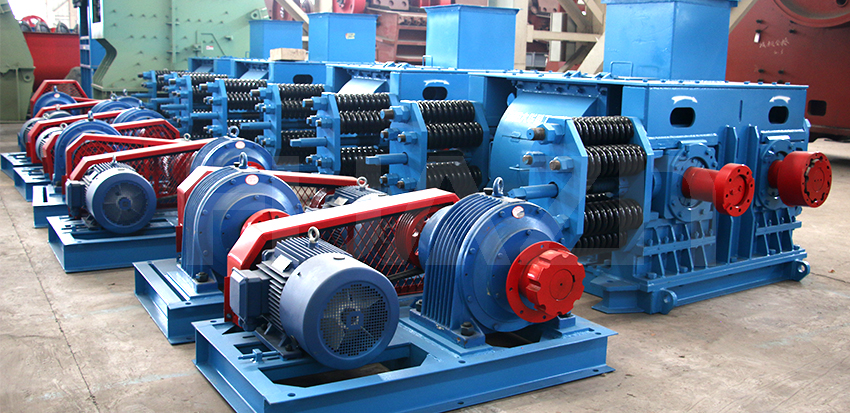

Roller Design: Are the rollers smooth, corrugated, or toothed? The surface pattern should suit your material and product shape requirements. Toothed rollers are better for crushing fragile materials, while smooth rollers are for fine crushing of hard, abrasive materials.

Roller Diameter and Width: Larger diameter rollers can accept larger feed sizes. Roller width impacts capacity. The ratio of diameter to feed size is a key design principle.

Adjustment Mechanism: How is the gap between the rollers adjusted? Look for a robust, reliable system (often hydraulic or mechanical screw) that allows for precise control over product size and easy unjamming in case of an overload.

Drive System & Power: What is the power rating (kW/HP) of the motor? Is it a single or dual motor drive? Ensure the power source matches your site’s electricity supply. The transmission (gear couplings, V-belts, etc.) should be sturdy and guarded.

Crushing Ratio: This is the ratio of the feed size to the product size. A standard double roller crusher typically offers a ratio of about 4:1. Understand if this meets your reduction needs in a single pass or if multiple crushing stages are required.

Machine Construction & Wear Parts: What is the frame made of (heavy-duty steel plate)? What is the composition of the roller shells? Are they made from high manganese steel or other wear-resistant alloys? Easy access for wear part replacement drastically reduces maintenance downtime.

3. Manufacturer Reputation & Support

Brand History and References: How long has the manufacturer been in business? Can they provide case studies or customer references from similar applications?

After-Sales Service: What is the warranty period and what does it cover? Is there a local dealer or service technician network for timely support? Prompt service is critical for minimizing operational disruptions.

Availability of Spare Parts: Are wear parts (roller shells, bearings, etc.) readily available? What is the typical lead time? A reliable parts supply chain is non-negotiable.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.