In the stone crushing production line, coarse crushing is the first and most critical stage. In this crushing stage, the large rocks are broken into small one for the further processing. The efficiency and performance of coarse crushing equipment directly impact the productivity and cost-effectiveness of the entire production line. This article explores the common types of coarse crushing equipment, the working principles, and applications.

Jaw Crusher

Working Principle:

A jaw crusher uses compressive force to break materials. It consists of two vertical jaws— fixed jaw plate and movable jaw plate. The movable jaw plate exerts pressure on the rock, crushing it against the fixed jaw until it breaks into smaller pieces.

Jaw crusher is for the primary crushing of hard and abrasive rocks(granite, basalt, quartz).

Advantages of jaw crusher

High crushing ratio. | Simple structure, easy maintenance. | Reliable performance with low operational costs.

Gyratory Crusher

Working Principle:

A gyratory crusher consists of a conical head gyrating inside a concave shell. The material is crushed between the mantle and the concave liner as the gyrating head applies continuous pressure.

Gyratory crusher is commonly used in large-scale mining and quarrying operations for high-capacity production lines.

Advantages of gyratory crusher:

Higher capacity. | Continuous crushing, higher efficiency. | Suitable for very hard and abrasive materials.

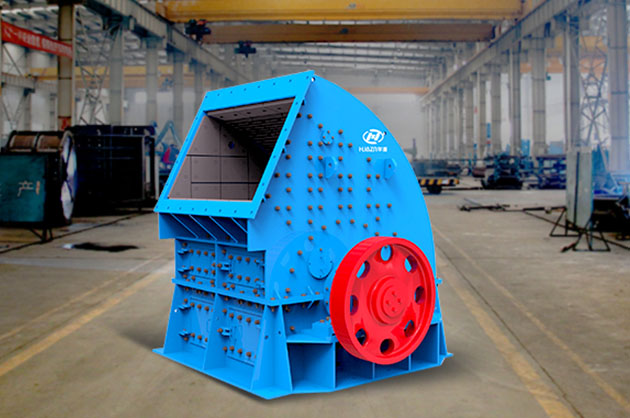

Impact Crusher

Working Principle:

Impact crushers use high-speed impact force to break rocks. The material is fed into a rotating rotor equipped with blow bars, which hurl the rocks against impact plates, causing them to break.

Impact crusher is used for the crushing of soft to medium-hard materials (limestone, dolomite).

Advantages of impact crusher:

Uniform & cubical product. | Lower energy consumption. | Adjustable output size.

Hammer Crusher

Working Principle:

A hammer crusher uses high-speed rotating hammers to strike and break the material. The crushed material is then discharged through a grate at the bottom.

Hammer crusher is designed to crush brittle and medium-hard materials (coal, gypsum, limestone).

Advantages of hammer crusher:

High reduction ratio. | Simple operation and maintenance. | Cost-effective for small to medium-scale operations.

Coarse crushing is a fundamental stage in the stone crushing production line, and selecting the right equipment is crucial for optimizing efficiency and reducing operational costs. Jaw crushers, gyratory crushers, impact crushers, and hammer crushers each have unique advantages depending on the material type, production capacity, and desired output. By carefully evaluating these factors, operators can ensure a smooth and productive crushing process, leading to higher profitability and better-quality aggregates.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.