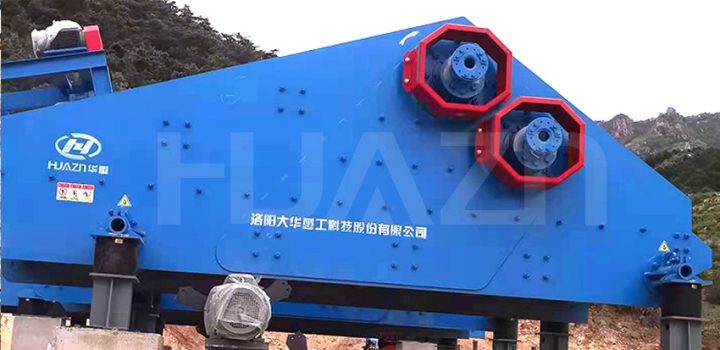

Linear Vibrating Screen

Max. Feed Size: 250 (mm)

Processing Capacity: 7.2-360 (t/h)

Application Fields: construction, coal, hydroelectricity, mining, plastic, chemical industry.

Applied Material: it is suitable for all kinds of materials.

Tel.: +86 13938852499 E-Mail: lydhchina@huazn.com

Overview

Linear Vibrating Screen is mostly used for selecting and classifying powdery and granular materials. It adopts the shock excitation of motor as vibration source to make materials tossed over screen and meanwhile move forwards.

Product Features

1.Small volume, light weight and simple structure altogether makes it easier for installation and maintenance.

2.High production capacity.

3.Low noise and consumption, high screening efficiency.

4.Advanced exocentric structure.

Working Principle

When the vibrating screen works, the two motors which are rotate synchronously in the reverse direction drive the exciter to produce reverse exciting force. It will force the screen bring sieve to make bouncing motion together, thus throwing up the material periodically under the effect of exciting force to realize classifying process.

Technical Parameters

| Model | Layer | Mesh Size (mm) | Double Amplitude (mm) | Vibrating Frequency (r/min) |

Max. feed size (mm) |

Capacity (t/h) | Power (kw) |

| ZKR1230 | 1 | 0.25-50 | 7-9 | 970 | 150 | 7~144 | 2×4 |

| ZKR1245 | 1 | 0.25-50 | 7-9 | 970 | 150 | 10-200 | 2×5.5 |

| ZKR1260 | 1 | 0.25-50 | 7-9 | 970 | 150 | 12~280 | 2×11 |

| ZKR1437 | 1 | 0.25-50 | 7-9 | 970 | 150 | 10~210 | 2×5.5 |

| ZKR1836 | 1 | 0.25-50 | 7-9 | 970 | 150 | 13~250 | 2×7.5 |

| ZKR1845 | 1/2 | 0.25-50 | 7-9 | 970 | 150 | 16~324 | 2×11/15 |

| ZKR1860 | 1/2 | 0.25-50 | 7-9 | 970 | 150 | 20~380 | 2×18.5/22 |

| ZKR2145 | 1 | 0.25-50 | 7-9 | 970 | 150 | 20~380 | 2×11 |

| ZKR2160 | 1/2 | 0.25-50 | 7-9 | 970 | 150 | 20~430 | 2×22/30 |

| ZKR2460 | 1/2 | 0.25-50 | 7-9 | 970 | 150 | 20~500 | 2×22/30 |

Customer Cases