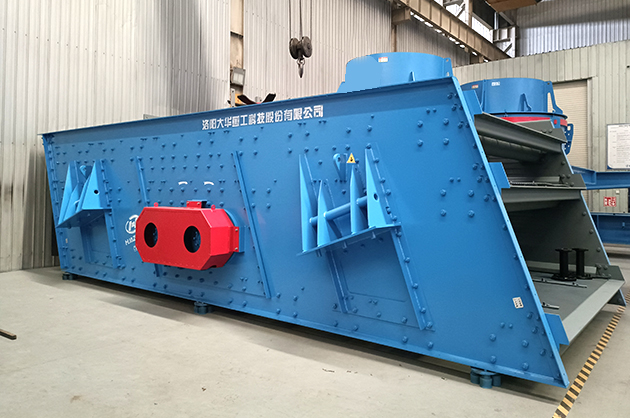

ZSW Series Vibrating Feeder

Max. Feed Size:

500/580/750/600x900x1200/700x1050x1400/800x1200x1600 (mm)

Processing Capacity: 150-1250(t/h)

Application Fields: mining, construction, metallurgy, cement, chemical industry.

Applied Material: ore with compressive strength less than 280 Mpa, rock, slag.

Tel.: +86 13938852499 E-Mail: lydhchina@huazn.com

Overview

ZSW Series Vibrating Feeders are linear feeders suitable to continuously and evenly feed block and granular materials to primary crusher, meanwhile having the function of pre-screening the materials.

Product Features

1.It is based on the principle that eccentric vibration of axis produces existing force.

2. Even vibration and smooth feeding contribute to a balanced production line.

3.While feeding, the pre-screening function can significantly increase crushing efficiency.

4.The physical design of adjustable grizzly bars has efficiently avoid material chock.

5.The adjustable-speed motor can be chosen to control the feeding amount without frequent start of the motor.

6.Low noise operation helps develop a better working environment.

7.High efficiency and feeding capacity, easy installation and maintenance, low operation cost.

Working Principle

The exciter works as the vibration source of the vibrating feeder which is composed of two eccentric shafts (driving shaft and driven shaft) and gears. The electromotor drives the driving shaft to rotate at high speed, the gear of the driving shaft engages with the driven shaft, and then the two shafts rotate together in the reverse direction that make the trough body to move forward the material continuously. When the material moves along the grizzly bar, the material that is smaller than the screen hole will drop down the gap between grizzly bar, thus realizing classifying.

Technical Parameters

| Model | Max. Feed Size | Rotating Speed | Capacity | Power | Inclination angle |

| (mm) | (r/min) | (t/h) | (kw) | (°) | |

| ZSW380×95 | 500 | 500-800 | ~150 | 11 | 0-10 |

| ZSW420×110 | 580 | 500-800 | 150~280 | 15 | 0-10 |

| ZSW490×110 | 580 | 500-800 | 150~350 | 18.5 | 0-10 |

| ZSW600×130 | 750 | 500-800 | 220~500 | 30 | 0-10 |

| ZSW600×150 | 900 | 500-800 | 260~620 | 37 | 0-10 |

| ZSW600×180 | 1050 | 500-800 | 400~1000 | 45 | 0-10 |

| ZSW600×210 | 1200 | 500-800 | 550~1250 | 45 | 5-10 |

| ZSW600×240 | 1400 | 500-800 | 600~1500 | 55 | 5-10 |

Customer Cases