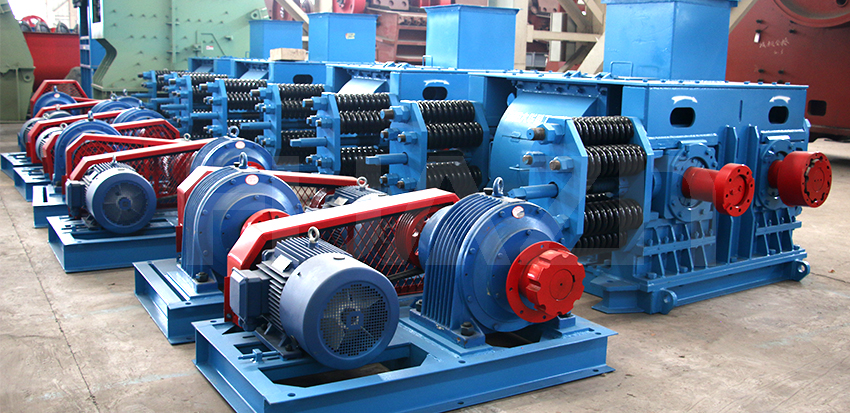

The roll crusher can handle both primary and secondary crushing, making the rock, coal suitable for various applications in mining, quarrying, and recycling industry. What is the maintenance and how to do the test for the roll crusher?

Maintenance of roller crusher

1. Non-crushed materials should be taken out before they get into the hopper. Iron mover or any other methods can be put to stop them.

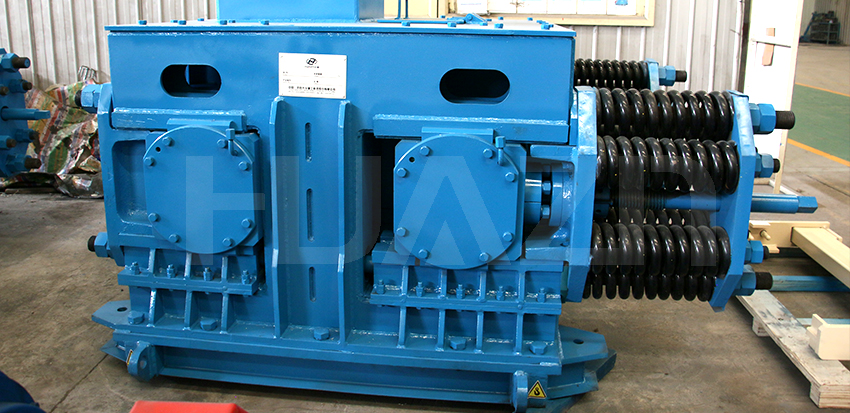

2. The safety adjustment springs must have enough compressive press during operation, to ensure the product granularity and output.

3. The materials while feeding cannot be too big for avoiding wearing of the roller husk.

4. Make sure the central line of roller shaft be parallel during operation.

5. The even feeding must be assured to avoid wearing of roller parts.

6. Regularly inspect the final granularity.

Test of roller crusher

After installing the machine completely, it can start test. If no problem after non-loading test for 4 hours, then the loading test can be started.

NO-LOADING TEST

The following items should be paid attention while test:

(1) Two electric motors of the crusher must be simultaneously started up.

(2) Listen carefully for the sounds of motor, reducer and bearings whether are normal.

(3) The temperature rise of bearing cannot exceed 35℃.

(4) The transmission should be steady, the vibration should be small and there is no unusual voice. If not, stop test and make inspection.

(5) After the test, all the connect joints should be tightening up again and inspect whether there is an abnormal phenomena on roller sheets, if is, remove it.

No-loading test must be 4 hours or more, and inspect the rise of temperature in each part, check operation sounds, current in motor and control bin whether are normal.

After the test, inspect the contact situation on friction surface of reducer whether it is normal, and whether any screw gets loose and remove them in time.

LOADING TEST

(1) After qualified non-loading test, start the loading test, and it is 8 hours.

(2) Loading test sequences are as follows:

a. The start-up sequence is:

Discharge conveyor → Crusher → Feed conveyor

b. The close-down sequence is:

Feed conveyor → Crusher → Discharge conveyor

c. The crusher must be started with non-loading, feed material until it becomes normal operation.

(3) The max feeding should be under designing rule. The over big material is prohibited to enter the crusher.

(4) It should be from few to more by degrees to full-loading while feedings, NOT allowed feed once fully.

(5) It should make equably distribution as the length of roller while feeding.

(6) Adjust the safety adjustment screw rod to make the discharge granularity is suitable according to the discharge granularity.

After loading test for 8 hours, it can be put into manufacturing if no problem.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.