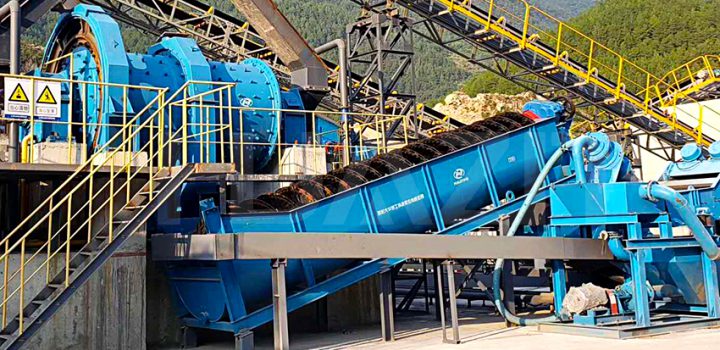

As a commonly used equipment for the production of sand and stone aggregate, the sand washing machine usually follows behind the sand making machine on the sand production line. Its function is to remove the soil and impurities from the sand. It can be said that the sand washing machine is an effective way to improve the quality of sand and stone aggregate. Sand washing machine can be used in construction sites, sand and stone production plants, concrete production lines and other industrial fields. There are two common types of sand washing machine: spiral sand washing machine and bucket wheel sand washing machine, so what is the difference between the two? Which one is better?

✼ Spiral sand washing machine

The screw device is set inside the spiral sand washing machine. When mixing the material, the water and the material are fully mixed. The impurities in the material are dissolved in the water and discharged from the outlet above the equipment, and the sand and stone are discharged from the top outlet under the drive of the spiral device, and the clean finished sand and stone are obtained.

| Type | Model | Spiral diameter (mm) |

Feed size (mm) |

Water Consumption(t/h) | Capacity(t/h) | Power(kw) | Dimension(mm) |

| Light single spiral | XL-508 | 508 | <10 | 6-60 | -20 | 7.5 | 8585×2347×1615 |

| XL-610 | 610 | <10 | 6-63 | -50 | 7.5 | 8166×2480×1720 | |

| XL-762 | 762 | <10 | 9-63 | -75 | 15 | 9070×2650×1870 | |

| XL-914 | 914 | <10 | 10-90 | -100 | 15 | 9310×2830×2360 | |

| XL-1118 | 1118 | <10 | 20-160 | -175 | 22 | 11830×3048×2230 | |

| Light double spiral | 2XL-762 | 762 | <10 | 20-150 | -140 | 2×15 | 9178×3625×1808 |

| 2XL-914 | 914 | <10 | 130-180 | -200 | 2×15 | 9310×3870×2134 | |

| 2XL-1118 | 1118 | <10 | 60-600 | -350 | 2×22 | 11830×4170×2230 | |

| Heavy single spiral | XLZ-762 | 762 | <60 | 160-220 | -125 | 30 | 7775×1290×2034 |

| XLZ-914 | 914 | <60 | 200-300 | -175 | 37 | 8324×1382×2112 | |

| XLZ-1118 | 1118 | <75 | 500-750 | -250 | 37 | 8703×1681×2176 | |

| Heavy double spiral | 2XLZ-762 | 762 | <60 | 300-400 | -150 | 2×30 | 7775×2090×2068 |

| 2XLZ-914 | 914 | <60 | 350-450 | -200 | 2×30 | 8324×2336×2112 | |

| 2XLZ-1118 | 1118 | <75 | 900-1100 | -300 | 2×37 | 8703×2861×2150 |

1. Large sand and stone processing capacity

Spiral sand washing machine adopts spiral device to stir mud, instead of “bucket” to scoop out mud, which has higher work efficiency and larger sand and stone processing capacity.

2. Longer service life

The spiral sand washing machine does not need to use the screen, which saves the wear of the screen part and the service life of the equipment is longer.

3. Better quality of finished products

Materials are turned and cleaned more times and more thoroughly in the spiral sand washing machine, so the quality of sandstone products is better.

4. Suitable for fine material

The spiral sand washing machine can clean fine materials, which is unable to be done by the bucket wheel sand washing machine.

✼ Bucket wheel sand washing machine

The bucket wheel sand washing machine is driven by power equipment. The impeller of the bucket wheel sand washing machine rotates in the circumferential direction in the water tank, driving the slurry to flip, stir and wash. The water-content material is dehydrated by the impeller and discharged to obtain clean finished materials.

| Type | Wheel Diameter(mm) | Wheel Width(mm) | Wheel Speed(r/min) | Capacity(t/h) | Power(kw) | Dimension(mm) |

| DXS2.8 | 2800 | 880 | 1.235 | 20-50 | 7.5 | 3875×2550×2910 |

| DXS3.2 | 3200 | 880 | 1.217 | 100-150 | 11 | 4547×3069×3400 |

| DXS3.6 | 3600 | 1200 | 1.09 | 130-190 | 15 | 4982×4146×3800 |

| DXS3.8 | 3800 | 1600 | 1.07 | 150-220 | 22 | 4978×5440×3798 |

| DXS3.8/3 | 3800 | 2400 | 1.09 | 250-350 | 37 | 4978×5440×3798 |

1. Reasonable structure and reliable operation

Bucket wheel sand washing machine can clean and separate the stone powder and mud in the sand, adopts advanced sealing structure, transmission part is isolated from water and sand, low failure rate, reliable transmission device to ensure the cleaning effect, is the advanced sand washing equipment in the supporting equipment of sand making machine.

2. Guaranteed output of finished products

The bucket wheel sand washing machine has high cleanliness, low power consumption, less sand loss in the sand washing process. The produced sands meet the requirements of high standard construction sand, and the product output is more guaranteed. It is the ideal choice for upgrading the domestic sand washing industry.

3. Save water resources

The bucket wheel sand washing machine does not need to use too much water resources in the process of washing the mechanical sand, stone powder and other impurities, saving water and realizing green production.

4. Simple maintenance

The failure rate of the parts of the bucket wheel sand washing machine is low, and the maintenance of other parts is simple and convenient except the screen mesh that needs to be replaced.

The specific selection of sand washing machine model depends on the nature of sand and stone materials, production conditions, procurement budget and other factors. If you don’t know how to choose the machine, please consult the online service, or contact by Whatsapp: +86 13938852499, the sales manager will give you the detailed configuration.